Sanding Sponge

what is a sanding sponge

A sanding sponge is a versatile tool used in woodworking, construction, and DIY projects. It’s a sponge with an abrasive surface used for:

- Smoothing Surfaces: Ideal for preparing surfaces for painting or refinishing.

- Contour Sanding: Flexible and perfect for curved surfaces.

- Finishing Touches: Achieves a polished finish on projects.

Advantages:

- Comfortable: Ergonomic design reduces hand fatigue.

- Reusable: Rinse and reuse for multiple projects.

- Precision: Offers precise control for excellent results.

Whether you’re a professional or DIY enthusiast, a sanding sponge is a handy tool for achieving smooth finishes on your projects.

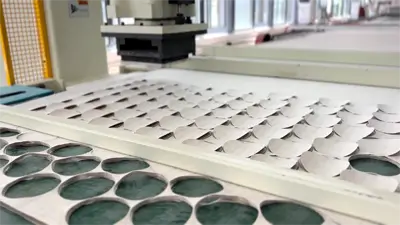

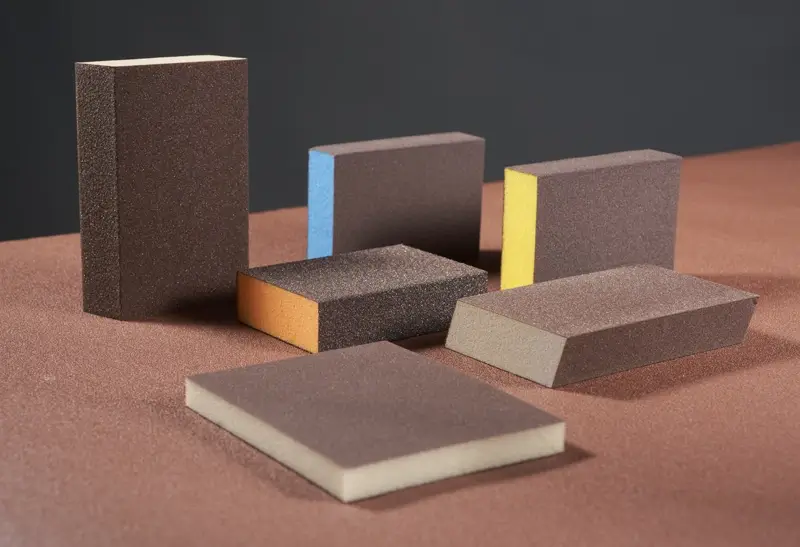

Sanding Sponge Products by QISHENG

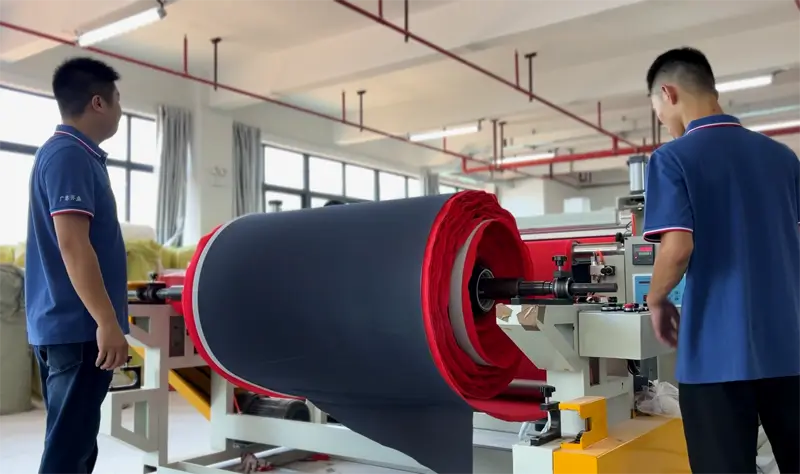

As a seasoned manufacturer with 15 years of expertise in abrasive product production, we excel in crafting a diverse array of Sanding Sponges. Our offerings encompass a wide spectrum, including Standard Sanding Sponges, Contour Sanding Sponges, Heavy-Duty Sponges, and more. Whether you’re a professional artisan or a dedicated DIY enthusiast, Qisheng’s products, marked by exceptional quality and innovation, are meticulously designed to cater to your exacting demands.

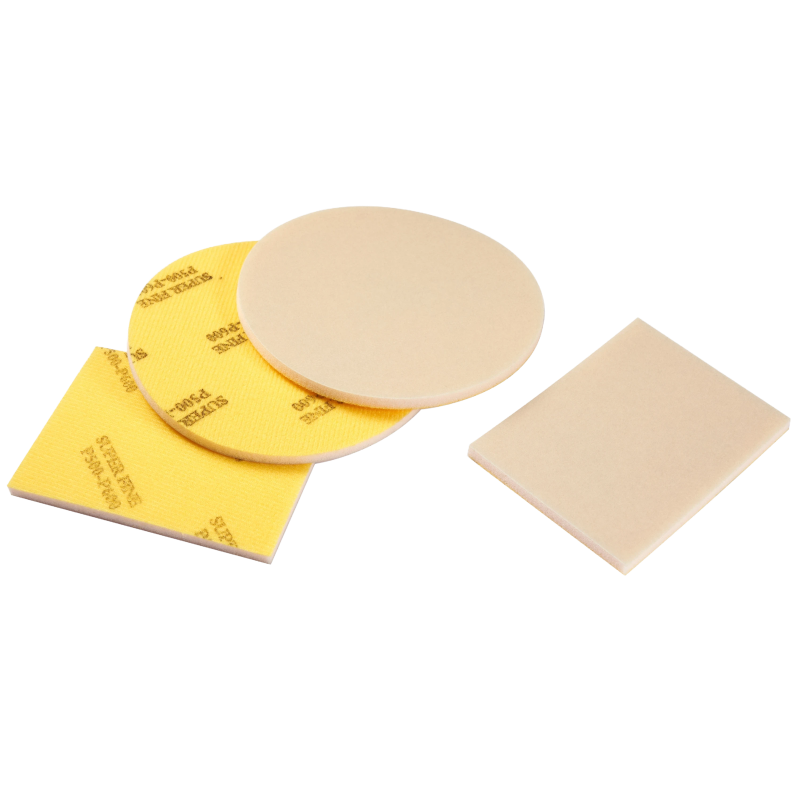

sanding sponge 320 grit

orbital sander sponge pad

round sanding sponge

1000 grit sanding sponge

How We Can Assist You

Product Customization

We understand that every project is unique. Our team is ready to work with you to customize Sanding Sponges to your precise specifications, ensuring they meet your project’s requirements perfectly.

Looking to promote your brand? Take advantage of our private labeling services. We can customize packaging and branding to reflect your company’s identity.

Competitive Pricing

We are committed to providing competitive pricing without compromising on quality. Our cost-effective solutions ensure you get the best value for your investment.

For wholesale clients, we offer flexible bulk ordering options. Whether you need a large quantity of standard sponges or specialized products, we can accommodate your volume needs.

Technical Expertise

Our team of experts is here to assist with any technical questions or challenges you may encounter. Whether it’s product selection or application guidance, we’re just a phone call or email away.

Quality Assurance, Timely Delivery

We take pride in our rigorous quality control processes. Rest assured that every Sanding Sponge leaving our facility meets the highest quality standards, ensuring your projects are completed flawlessly.

We understand the importance of deadlines. With efficient logistics and a commitment to on-time delivery, we ensure your orders arrive when you need them.

Application Areas

Woodworking

Achieve smooth and polished wood surfaces for cabinetry, furniture, and woodworking projects. Our sponges are perfect for preparing, finishing, and refinishing woodwork.

Drywall and Plastering

For drywall and plastering tasks, our sponges offer the finesse needed to achieve a smooth, seamless finish.

Automotive Refinishing

Whether you’re working on auto body repair or refinishing, our sponges are up to the task. They are designed to handle the intricacies of automotive surfaces.

Metal Fabrication

From deburring to polishing metal surfaces, our Heavy-Duty Sponges are indispensable in metalworking applications. They make challenging tasks more manageable.

DIY and Home Improvement

Empower DIY enthusiasts with the tools they need to tackle home improvement projects. Our user-friendly Sanding Sponges are perfect for small-scale renovations and repairs.

Arts and Crafts

Artists and crafters appreciate the precision and flexibility of our Contour Sanding Sponges. They are ideal for creating intricate shapes and finishes in art projects.

FAQS

can sanding sponges be washed?

Yes, sanding sponges can be washed. Many sanding sponges are designed to be reusable, and washing them can help extend their lifespan. Here’s how to wash a sanding sponge effectively:

Rinse with Water: After use, rinse the sanding sponge thoroughly with clean water. This will remove any sanding debris, dust, or particles from the abrasive surface.

Use Mild Soap (Optional): If the sponge is particularly dirty or caked with material, you can use a mild soap or detergent. Gently scrub the sponge with the soap, then rinse it thoroughly with water to remove all soap residues.

Squeeze Out Excess Water: Squeeze the sponge to remove excess water. Ensure it’s not sopping wet but slightly damp.

Let it Air Dry: Place the washed sponge in a clean, dry area with good airflow to allow it to air dry completely. Avoid direct sunlight or heat sources, as excessive heat can damage the sponge.

Inspect Before Reuse: Before using the sponge again, inspect it for any signs of damage, wear, or loss of abrasive material. If it’s still in good condition, you can reuse it for your sanding tasks.

Properly cleaning and maintaining your sanding sponge not only extends its life but also ensures that it continues to perform effectively for your projects.

what are sanding sponges for?

Sanding sponges serve various purposes and are a valuable tool in several industries and applications. Here’s what sanding sponges are primarily used for:

Smoothing Surfaces: Sanding sponges are used to smooth rough or uneven surfaces. This includes preparing surfaces for painting, staining, or varnishing by removing imperfections.

Contour Sanding: Their flexible nature makes sanding sponges perfect for sanding curved or contoured surfaces, such as molding, trim, or curved furniture pieces.

Finishing Touches: Fine-grit sanding sponges are commonly used for finishing touches on woodworking and other projects. They help achieve a polished and professional-looking surface.

Removing Material: Sanding sponges are effective in removing materials like old paint, rust, or adhesive residues from various surfaces, including wood, metal, and plastic.

Drywall Finishing: In construction, sanding sponges are used for drywall finishing to create smooth and even walls or ceilings before painting or wallpapering.

Automotive Refinishing: Sanding sponges are employed in automotive refinishing to prepare surfaces for paint or repair work, including sanding primer or removing old paint.

Marine Applications: In boat building and maintenance, sanding sponges are used to smooth surfaces, repair gel coat, and prepare boats for painting or varnishing.

Metalworking: For metalworkers, sanding sponges assist in deburring, polishing, and preparing metal surfaces for welding, painting, or other finishing processes.

DIY Projects: Sanding sponges are a popular choice among DIY enthusiasts for a wide range of home improvement and craft projects.

Artistic Creations: Artists and crafters use sanding sponges to shape and finish materials like wood, clay, or foam in art and craft projects.

In essence, sanding sponges are versatile tools that can be used in various industries and applications where precision, flexibility, and ease of use are required for achieving smooth and polished surfaces. They are valued for their ability to conform to different shapes and their effectiveness in both professional and DIY settings.

are sanding sponges reusable?

Yes, sanding sponges are generally reusable. Their design allows for multiple uses before they wear out, making them a cost-effective choice for sanding tasks. To maximize their lifespan and reuse them effectively:

Clean After Use: After sanding, clean the sponge by rinsing it with water to remove dust, debris, and any residual materials.

Dry Thoroughly: Squeeze out excess water and allow the sponge to air dry completely. Ensure it’s stored in a dry, cool place.

Inspect for Damage: Before each reuse, inspect the sponge for signs of wear, tear, or loss of abrasive material. If it’s still in good condition, it can be reused.

Proper Storage: Store your sanding sponges in a clean, dry container or bag to protect them from dust and contaminants when not in use.

By following these steps and taking care of your sanding sponges, you can extend their life and get multiple uses out of them, making them an economical choice for your sanding and finishing needs.

What are the different types of sanding sponges??

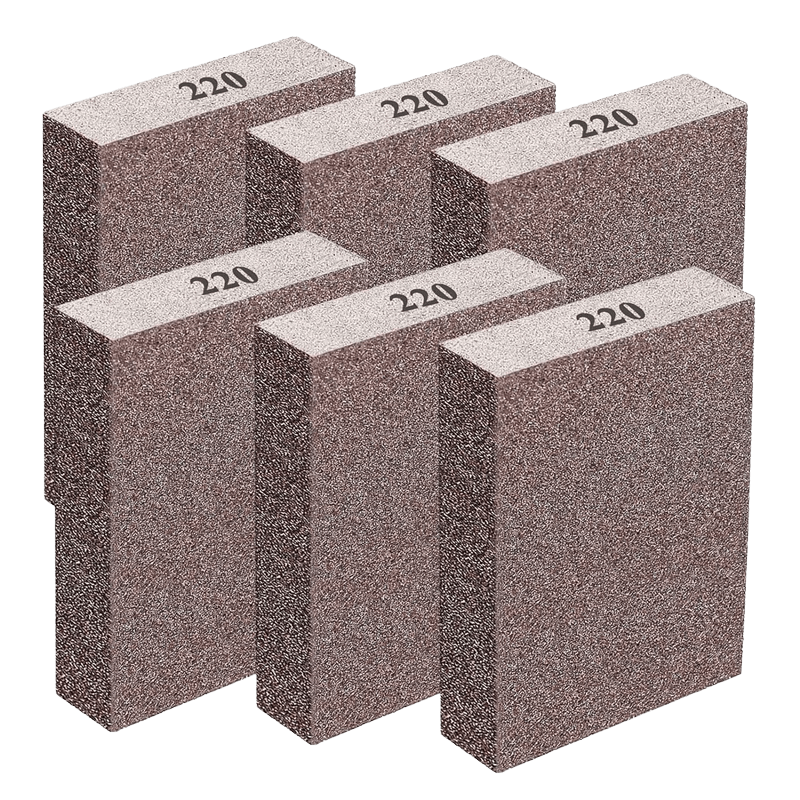

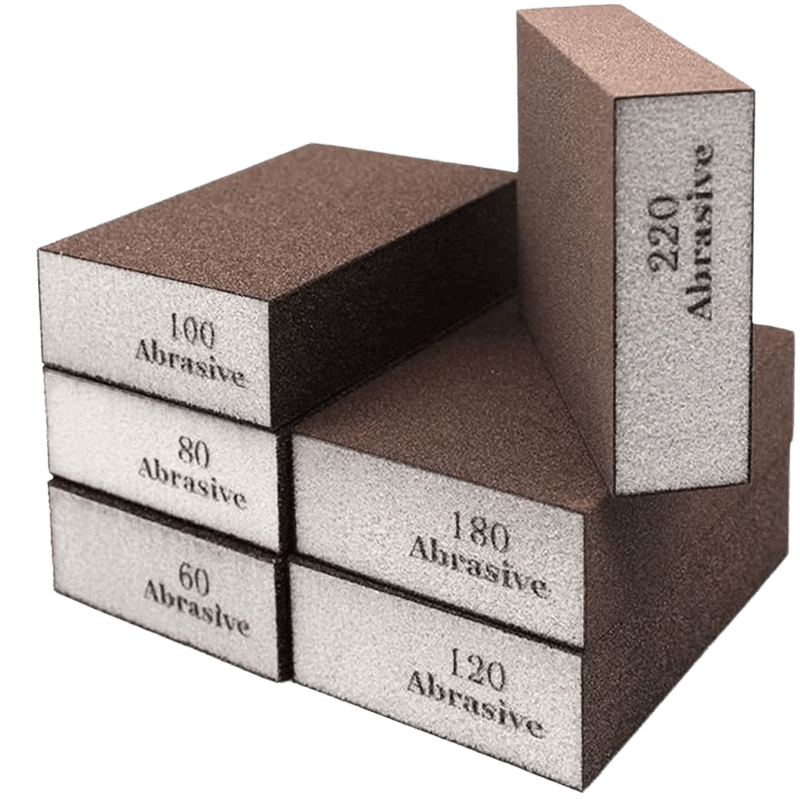

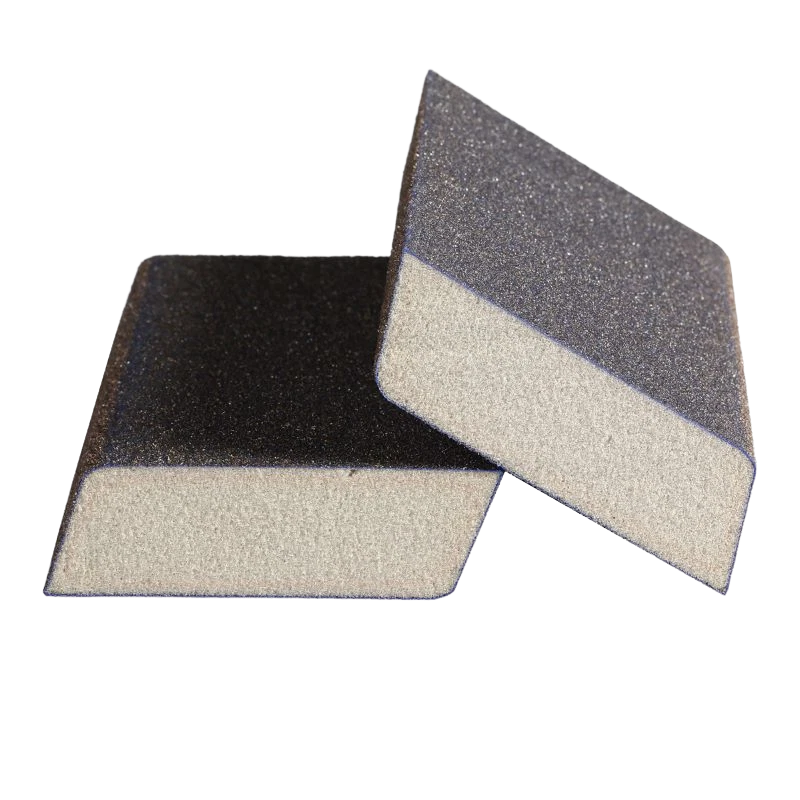

Standard Sanding Sponges: These are the most versatile and widely used sanding sponges. They come in various grit levels for tasks ranging from rough surface preparation to fine finishing.

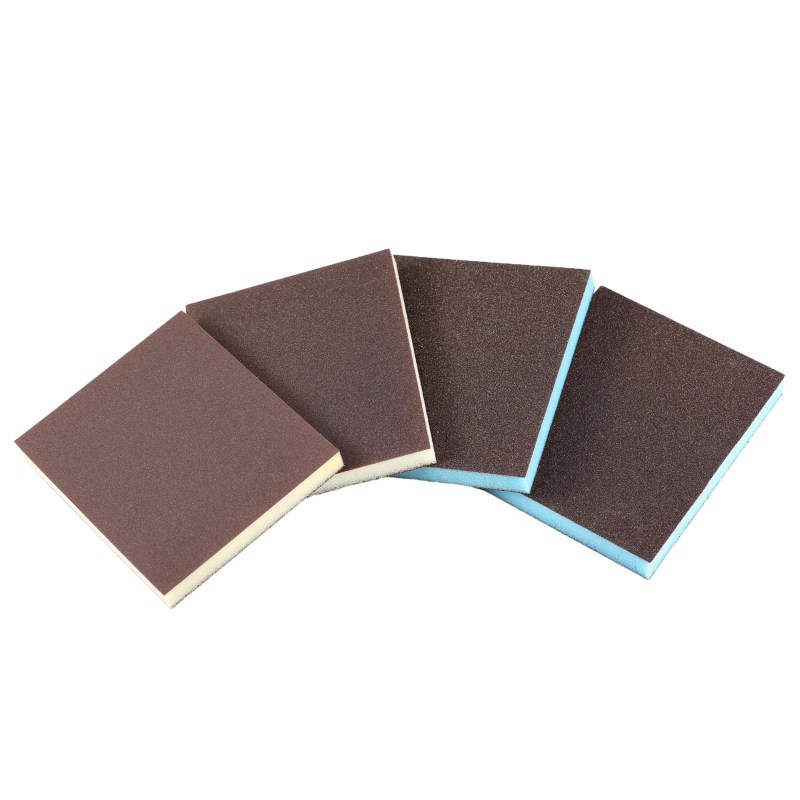

Contour Sanding Sponges: Contour sponges are designed to conform to irregular or curved surfaces, making them perfect for intricate woodwork, carvings, and other projects where standard sanding tools may not be effective.

Fine Finishing Sponges: Fine-grit sponges are used for the final touches on a project. They are excellent for achieving a smooth, polished finish on surfaces before painting, staining, or varnishing.

Heavy-Duty Sponges: These sponges are reinforced for durability and are ideal for tough tasks such as removing paint, rust, or corrosion from metal surfaces. They are also suitable for smoothing rough wood.

Detail Sponges: Detail sponges are typically small and designed for precision work. They are useful for getting into tight spaces or for delicate sanding tasks.

Drywall Sponges: Drywall sanding sponges are specifically designed for smoothing drywall joints and seams. They have a rougher surface to quickly remove excess joint compound.

Automotive Sanding Sponges: These are specialized sponges for automotive refinishing and repair. They are designed to handle the unique needs of automotive surfaces.

Marine Sanding Sponges: Marine sponges are engineered to withstand the challenges of marine environments and are used in boat building, maintenance, and repair.

Metalworking Sponges: These sponges are designed for use on metal surfaces, including deburring, shaping, and smoothing metalwork.

Specialty Sponges: Specialty sponges are tailored for specific applications, such as those in the arts and crafts industry. They may have unique shapes or materials designed for particular tasks.

what are sanding sponges for?

Sanding sponges serve various purposes and are a valuable tool in several industries and applications. Here’s what sanding sponges are primarily used for:

Smoothing Surfaces: Sanding sponges are used to smooth rough or uneven surfaces. This includes preparing surfaces for painting, staining, or varnishing by removing imperfections.

Contour Sanding: Their flexible nature makes sanding sponges perfect for sanding curved or contoured surfaces, such as molding, trim, or curved furniture pieces.

Finishing Touches: Fine-grit sanding sponges are commonly used for finishing touches on woodworking and other projects. They help achieve a polished and professional-looking surface.

Removing Material: Sanding sponges are effective in removing materials like old paint, rust, or adhesive residues from various surfaces, including wood, metal, and plastic.

Drywall Finishing: In construction, sanding sponges are used for drywall finishing to create smooth and even walls or ceilings before painting or wallpapering.

Automotive Refinishing: Sanding sponges are employed in automotive refinishing to prepare surfaces for paint or repair work, including sanding primer or removing old paint.

Marine Applications: In boat building and maintenance, sanding sponges are used to smooth surfaces, repair gel coat, and prepare boats for painting or varnishing.

Metalworking: For metalworkers, sanding sponges assist in deburring, polishing, and preparing metal surfaces for welding, painting, or other finishing processes.

DIY Projects: Sanding sponges are a popular choice among DIY enthusiasts for a wide range of home improvement and craft projects.

Artistic Creations: Artists and crafters use sanding sponges to shape and finish materials like wood, clay, or foam in art and craft projects.

In essence, sanding sponges are versatile tools that can be used in various industries and applications where precision, flexibility, and ease of use are required for achieving smooth and polished surfaces. They are valued for their ability to conform to different shapes and their effectiveness in both professional and DIY settings.

sanding sponge vs sandpaper?

Sanding Sponge: Flexible, comfortable grip, reusable, ideal for contouring and detail work.

Sandpaper: Available in various grits, affordable, covers larger areas, suitable for heavy material removal.

The choice depends on the task and your preferences. Sanding sponges offer precision and comfort, while sandpaper provides versatility and grit options.